CLM Pro | RC models | RC gliders | Sailplane | Fuselage set | Pod | electric pod | Carbon Accessories | F5J | F3J | Ales | Slope | F3K | DLG | HLG | Kit | ARF |

Ballistic Kevlar-aramid 468 g/m² – plain

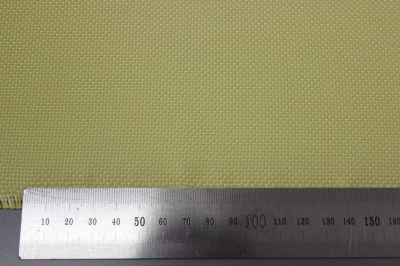

Ballistic Kevlar-aramid 468 g/m² – plain

High quality ballistic kevlar - aramid 468 g/m², 13.8oz/yd² – plain cloth. This fabric is specially made for ballistic protection.

High quality ballistic fine kevlar - aramid fabric 468 g/m², 13.7 oz/yd² – plain cloth - sample A4. The material is thick, opaque and compact in the middle.

This fabric is specially made for ballistic protection.

Ballistic results: (V-50, clay backed): 44 mag swc, 16 layers, 474 m/sec

It is only an sample of the material, A4 20x30cm / 11.81“x7.87“

If you a interested you can also get sheet by your desired dimensions.

What is Ballistic Kevlar®?

Kevlar®, a tightly woven, synthetic material with high tensile strength, was originally developed by the DuPont company in an effort to create a polymer-based replacement for tires — one that was lighter and more durable than its predecessor.

Upon discovering the potential behind this incredible strong fiber, the product, soon to be known as Kevlar®, was tested, and researched noticed that it exceeded the strength of nylon.

By the early 1970s, Kevlar® was introduced to the public and has since been used in a variety of industries including aerospace, ballistics, automotive, and telecommunications.

Still many feel that the Kevlar® name is synonymous with bullet resistant vests, and it’s durable, strong, and lightweight properties consistently place it ahead of steel and a variety of other materials when attempting to create or obtain effective body armor.

Kevlar® is a synthetic polymer and aramid fiber that is considered to be five-times stronger than steel on a equal weight basis. Its strength is derived from its structure (tightly packed, long chains of ring-like molecules) and way the fibers are tightly woven together.

The science used to create Kevlar® can be complex, and it’s easy to spend hours explaining its chemical makeup, but the take away will always be the same – it’s incredible strong and quickly showed its strength when compared to it’s nylon, polyester, and even steel predecessors.

As a DuPont product, Kevlar® is a product of years of extensive ballistic testing, scientific discovery, and engineering ingenuity. As such, Kevlar® products are tested for impact of ammunition between .22 caliber and .50 caliber.

|

Specification: |

||

|

|

Nominal |

Tolerance: |

|

Fiber: |

Kevlar-aramid 468 g/m², 13.8 oz/yd² |

|

|

Fibre description |

Aramid fiber 3300 dtex |

|

|

Weight: |

468 g/sqm / 13.8 oz/yd² |

± 3% |

|

Thickness: |

0.64 mm |

± 10% |

|

Weave: |

plain |

|

|

Width: |

125 cm |

|

|

Tensile strength (MPa) |

2863 |

|

|

Tensile modulus (GPa): |

67 |

|

|

Elongation at break (%): |

3.7 |

|

|

Ballistic results |

(V-50, clay backed): 44 mag swc, 16 layers, 474 m/sec |

|

|

Warp – Weft ratio: |

||

|

|

Warp |

Weft |

|

Fibre description: |

Aramid fiber 3300 dtex |

Aramid fiber 3300 dtex |

|

Thread count (ends/cm) |

6.7 |

6.7 |

|

Weight distribution (g/mq) |

230 |

230 |

|

Weight distribution (%) |

50 |

50 |

|

Total weight rate (%) |

50 |

50 |

|

Yarn number |

3300 tex |

3300 tex |

Reviews

Our facebook page

© Copyright 2018 by CLM-Pro